The pressure of the IoT revolution on traditional military embedded systems is the same as that on the implementation of consumer electronics design; The reduction of size, weight and power consumption (SWaP) is the key driving force behind each new product development and design. Generally speaking, embedded designers have been hoping to benefit from shorter development cycles and lower design risks, while the physical module system (SoM) has been trying to cope with these pressures.

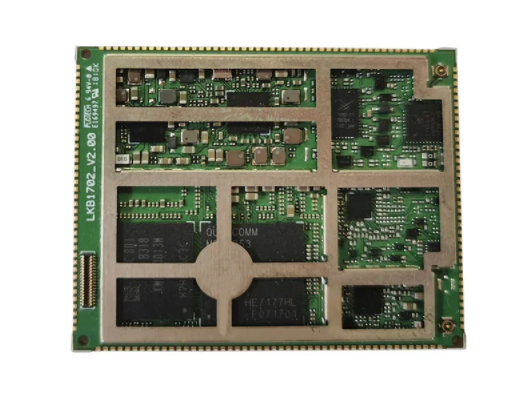

Traditional SoM designs require (at a minimum) a dual PCB solution, which can double the thickness and weight. The relatively large floor area also determines the need for larger dimensions in terms of width and height. Although this inherent defect is most obvious in wearable devices and other applications, it is also important to minimize the space requirements of each IOT terminal device in practical applications.

In addition to physical properties, due to the need to use necessary connector coordination, the electrical performance may encounter the problem of poor signal integrity, which may lead to failures under shock and vibration, and will significantly increase the cost of the overall Internet of Things design. With the increase of processor complexity, designers will have to squeeze more functions into a limited number of pins. Designers of less complex IoT devices may face similar problems, and they need to pay for redundant SoM functions they do not need.

Finally, IoT solution designers and original equipment manufacturers (OEMs) are now beginning to realize the security of their technology exposure in the well-known cloud - traditional SoM design means relying on a third party to implement the core processing functions of their products.

Virtual SoM can use today's high-quality PCB design software as a "template" to conduct rapid single PCB design between different processor manufacturers. Performance level requirements and multiple virtual SoM functions coexist perfectly - all these technologies can simplify the usually lengthy design cycle.

Virtualized SoM can maximize SWaP requirements while leveraging the small amount of physical SoM that still exists in IoT design, thereby reducing design complexity, cost, risk, and time to market. The latter point is particularly urgent as OEMs are competing with each other to bring their Internet of Things (IoT) solutions to market.

So, under this trend, will the traditional SoM be eliminated one day? At least not yet. When designing high-end x86/x64 platforms, it still has significant advantages, because faster and faster signals will lead to higher design complexity, and reinventing the wheel is not a prudent and good method. The Internet of Things hopes to find adopted design methods in the gateway of the Internet of Things with high local processing requirements, and further link them to the cloud and big data analysis.

The traditional SoM format is not the choice of most current IoT hardware design, while the virtual SoM design method is adding impetus to the rapid development of the real world deployment of the Internet of Things (IoT) we need.

If you have any questions about SOM and SBC, please feel free to contact Graperain, and we will be glad to receive your email.